shear box test

Using the secondary development function of MatDEM, the conventional direct shear test and torsional shear test are realized. See user_Box Shear for an example.

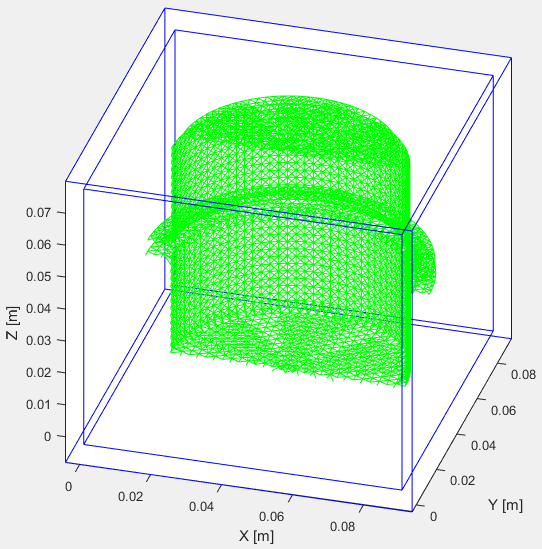

Using the basic disc modeling function, the structure of each component of the sample box (lower sample box, upper sample ring and upper pressure plate) is established. The discrete element model of the sample device is established by assembling these components in Box.

Using MatDEM's automatic stacking function and sample cutting, the geometric model of the specimen for direct shear test is established.

Put the sample into the sample box, the gravity stacking is made again, so that the sample is in close connect with the box.

The unit coordinates of lower sample box and upper sample ring are locked, the xy coordinates of upper pressure plate are locked, and put on vertical downward force to produce specific pressure. Move the upper sample box to the right step by step and the simulation of direct shear test is realized. The following graph is the animation of the sample's process.

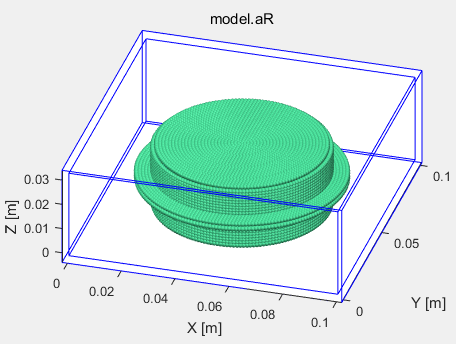

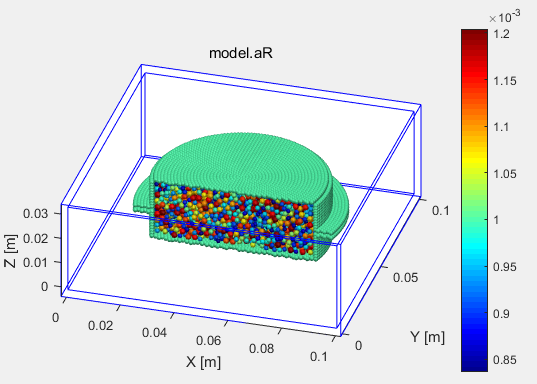

Based on the direct shear test, change the sizes of teh sample box and rotate the lower sample box to realize torsional shear test simulation.

Torsional shear test mesh profile.